Introduction of Waste Tire Sidewall Cutter

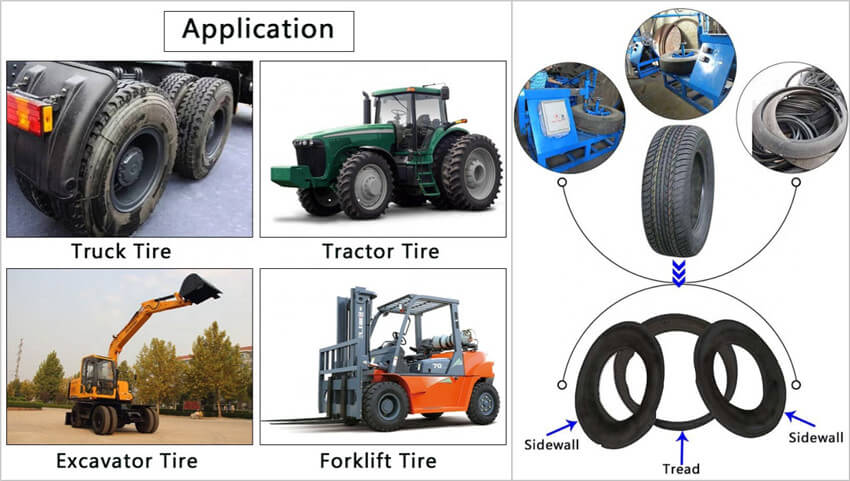

Waste tire sidewall ring cutter is mainly used to cut the sidewall of the steel wire tire to be recycled for the next step of segmentation. This tire cutter is special equipment to cut and separate tire bead ring, tire sidewall and tire crown of waste tires, which is the first process of treating waste tires.

Highlights of Waste Tire Sidewall Cutter

1. Long service life, high-quality tool steel of fixed blade and high hardness degree of movable blade cutting edge.

2. Simple to operate, easy to maintain.

3. Auto self-lift equipment, reduce labor.

4. Low energy consumption, high working efficiency.

5. Simple structure, small weight, and small space.

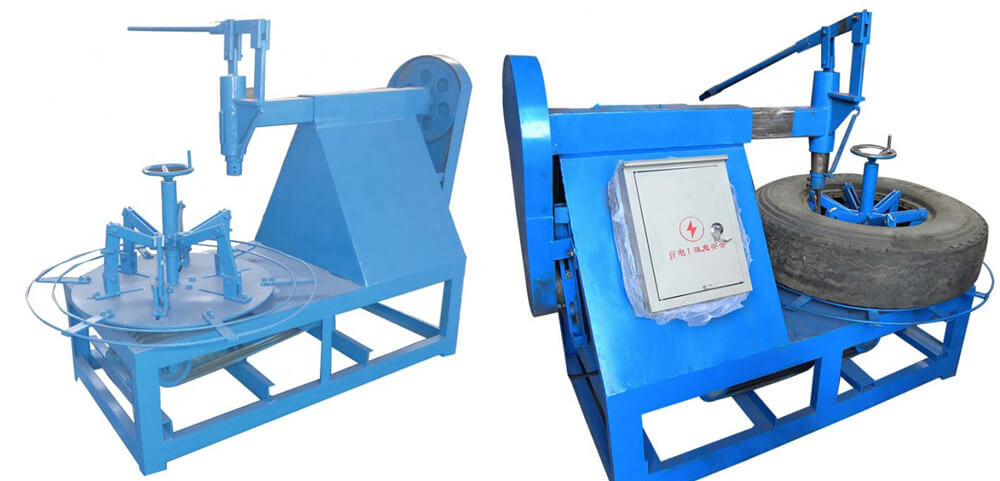

Structure and Principle of Tire Ring Cutter

The tire ring cutting machine consists of frame, rotate mechanism, prop mechanism and knife mechanism.

* First, put the tire on the platform, then rotate the handwheel, the three claws will stick the inner tire firmly.

* Second, start the power at low speed by a reduction drive mechanism, and work platform will rotate. The knife is set on the machinery panel and it can be moved forward and back at one’s ease.

* With the rotating of the tire, the knife cuts into the tire to cut open it successfully.

Tips: In order to cut the tire even smoothly and cool the knife, you can use a water pump to inject cooling water to the cutting point.

Main Technical Data of Waste Tire Ring Cutter

|

Model

|

TKIA-20

|

|

Motor Power

|

5.5kw

|

|

Speed of Main Screw

|

46.8r/min

|

|

Max Tire Diameter

|

1200mm

|

|

Knife Material

|

YJ-8 Alloy Steel

|

|

Weight

|

450kg

|

|

Overall Size

|

1285*1020*1500mm

|