Introduction of Rubber Crusher

Rubber crusher, as the main machine in a tire recycling line, is used for crushing the rubber blocks into 5-60 mesh rubber powder. The two rollers of rubber crusher make the relative rotation in different velocity. Rubber blocks are drawn into the gap of the two rollers for machining. By adjusting the roll gap, we get rubber powder of different sizes. The size of the final crumb can reach 5-60 mesh. The larger size has a higher capacity.

Features of the Cracker Mill

1. Compact structure, easy to install.

2. High hardness, high abrasion resistance.

3. Easy to operate and maintain.

4. High efficiency, labor-saving.

5. Adopt roller bearing, small frictional resistance, saving energy.

Structure of Rubber Crusher

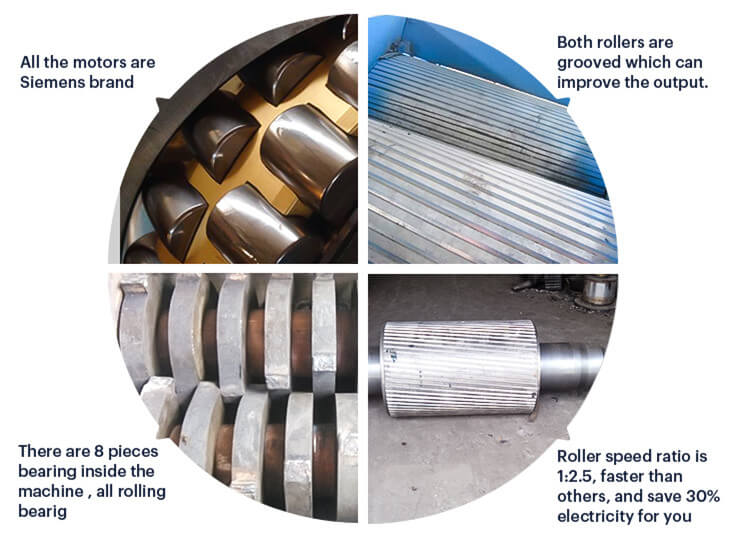

The cracker mill is consists of pedestal, frame, front and back rollers, speed reducer, electric motor, gap adjusting device, safety switch and electric control system.

1. Front Roller and Back Roller

The rollers are made of composite alloy, having a surface of high hardness and high abrasion resistance. The back roller is a grooved roller, having a long service life.

2. Gap Adjusting Device

The gap adjusting device of the tire crusher is a parallel square screw rod push-type, easy to operate and save labor. By turning the handwheel, the roll gap can be adjusted conveniently. The left side and right side should be parallel when adjusting the clearance, otherwise, the excessive inclination of the roller will damage the bearing.

3. Roller Temperature Adjusting Device

The rollers of the cracker mill are hollowed for heating and cooling. Steam or cooling water can be introduced into the rollers through the device so that the surface temperature can be adjusted to meet the process requirement.

4. Speed Reducer

The drive system of the rubber crushing machine adopts NGW planetary gear reducer, having high efficiency and low noise.

5. Electric Control System

An overload protective device is mounted on the crusher to protect the major parts from being damaged due to overload.

Specifications of Rubber Crusher

| Model | Drum diameter | Drum length | Front roll linear | Roll speed ratio | Max roller spacing | Motor |

| TKIA-350 | 300mm | 500mm | 26.2m/min | 1:2.5 | 8mm | 30kw |

| TKIA-400 | 400mm | 600mm | 34.5m/min | 1:2.5 | 8mm | 45kw |

| TKIA-450 | 450mm | 760mm | 38.0m/min | 1:2.5 | 8mm | 55kw |

| TKIA-560 | 560mm | 800mm | 38.6m/min | 1:2.5 | 8mm | 75kw |

| TKIA-560D | 560mm | 1000mm | 42.5m/min | 1:2.5 | 8mm | 132kw |